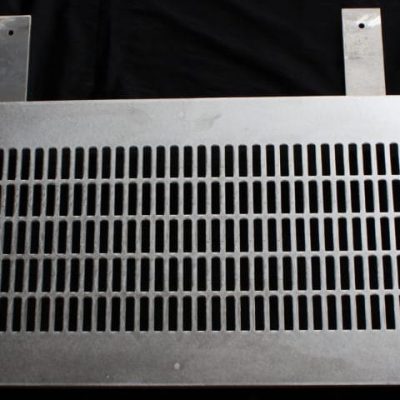

Industrial Perforated Metals

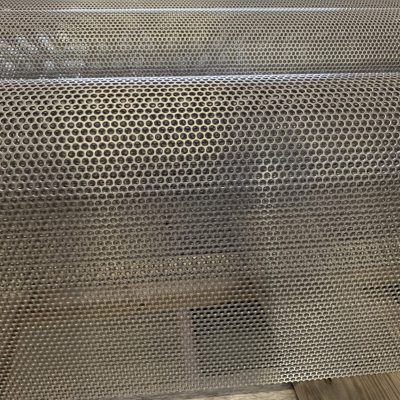

Filtration and separation are the primary reasons perforated metals are used in industrial equipment. After more than 30 years in the business, Astro provides complete fabricated and perforated solutions for your industrial needs.

INDUSTRIES THAT USE PERFORATED METALS

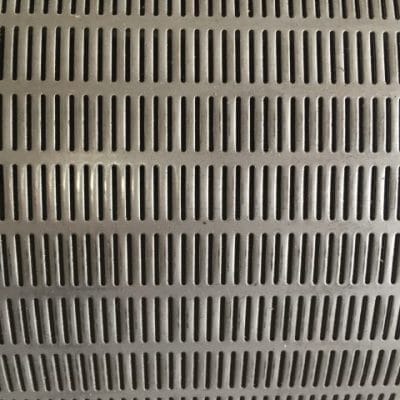

- Agriculture (Food and Beverage): Especially used for grain dryers, silo ventilation, hammer mill screens, threshing machine screens, wine vats, fish farms, sorting machines, beehive structures, coffee screens, fruit and vegetable juice presses and baking trays.

- Chemical and Energy: Mainly used as filters, gas purifiers, mine cages, shale shaker screens, aggregate screens, coal washing, battery separator plates, drying machine baskets, liquid gas burning tubes, and centrifuges.

- Material Development: Used for blast furnace screens, textile printers, felt mills, cinder screens, dyeing machines, cement slurry screens and glass reinforcement.

- Water Treatment Plants: Used for sludge filters, perforated rotary drum screens, drainpipes, etc.

We work with original equipment manufacturers (OEM’s) and engineering firms. When requested, we help our customers in design revisions for manufacturability and cost savings on projects. Indeed, it’s the combination of experienced staff, Solidworks proficiency, and machine capabilities that we provide this value.

Industrial Perforated Metal Punches: Trumpf TruPunch 3000 and 5000

We have two amazing punching machines we use for industrial perforated metals. These “top-of-the-line” machines for perforating allow us meet tight production schedules. Our perforating capabilities – combined with complete metal fabrication competency – means you can count on us for your full metal fabrication needs.

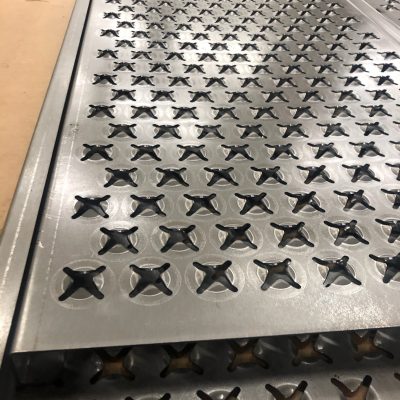

At Astro, we have the ability to order special cluster punches as it make sense per order. Of course, our experience and skill in using and sharpening cluster punches for clean cutouts with minimal burr provides benefit to our customers.

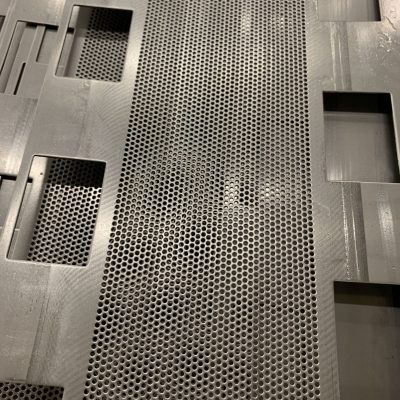

Integrating Perforating with other Operations

Perforating the metal is often just one step in the process of completing the piece of industrial equipment. For example, some parts need a blank to be cut on the laser, prior to perforating. After perforating, this part will go to forming. Then it will go to welding. Finally, it’s a complete piece of equipment. The process is different for each order we receive for industrial equipment, of course.

Astro has 30,000 square feet of space filled with metal fabrication equipment. This includes press brakes, lasers, a shear, a machining center and machining department, a lot of welders, a CNC auto mitering saw, and metal finishing equipment. Also, our highly trained shop crew has years of experience.

About Astro

Astro’s fabricating expertise includes cutting, forming, certified welding, machining, and assembly. Thus, Astro’s proficiency and competency in perforating metal means our customers get their metal fabrication projects completed in one location. For these reasons, we are the go-to fab shop for many when it comes to custom industrial perforated metal. Nevertheless, call us today at 763-777-8087 for your next project!