Fabrication of Quality Weldments

There are many aspects that go into the fabrication of quality weldments for use in industrial equipment. Here at Astro, we fabricate frames, tanks, spiral chutes, augers, and many other component parts for various OEM’s. At Astro, it starts with our passion: We make metal Perform. From this passion, through continuous improvement, we have built our quality system that we and our customers count on. Hence, fabrication of quality weldments for use in industrial equipment has many aspects. Here they are:

1. Fabrication: Top Notch Welding

1. Fabrication: Top Notch Welding

Our expertise in welding stainless and aluminum welding ranks up there with the best. The fabrication of quality weldments begin with experienced welders and an on-staff manufacturing engineer/CWI (Certified Welding Inspector). In fact, our CWI oversees our welding procedures and is a major component of our quality system. By industry standards, certified welding is the best way to ensure top quality welding. Please note, not all our customers require certified welding in their work. However, having the program in place along with the experience of our drafters, welders, and designers, assures we do some darn good welding. For example, see our certified welding.

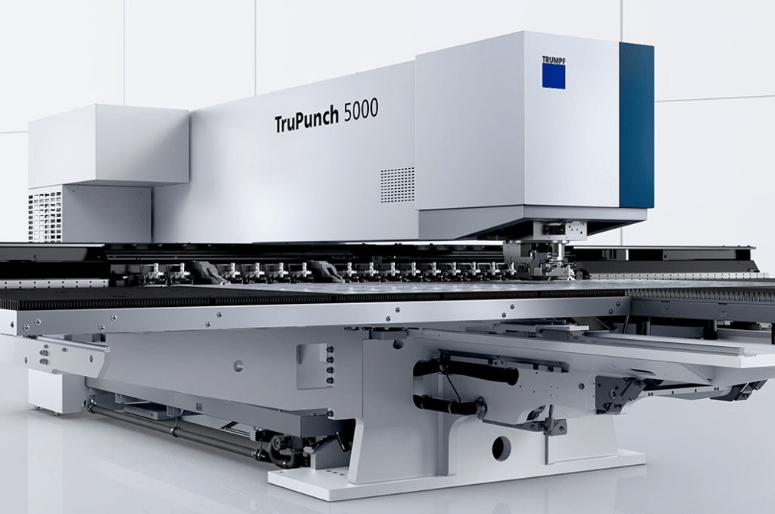

2. Quality Weldments: Equipment

With in-house laser cutting, punching, forming, saw cutting, shearing, machining, and welding, we have control over both the quality and thetimeliness of all the components that go into each weldment. The welding equipment is modern, and specifically for the best available for the types of welds we produce. All the welding machines are calibrated regularly. Indeed, our CNC punches do all our perforating in-house. Therefore, this enables us to completely fabricate equipment for the filtration industry, the food processing industry and others.

3. Quality Weldments: People and Process

Much of our work starts with the collaborative planning process. Therefore, most of our clients have prints or concept drawings from which to begin. Our staff is highly experienced in helping to solve customers’ problems. This could include design revision for efficiency and manufacturability, substitution of components/materials when the specified one is not available (which happens more often than one would think) and hitting promised ship dates.

This is how we meet the metal fabrication requirements of our clients across numerous industries. Thus, industries include: industrial water, oil and gas filtration, food processing, material handling equipment, the light rail industry, and more.

This is how we meet the metal fabrication requirements of our clients across numerous industries. Thus, industries include: industrial water, oil and gas filtration, food processing, material handling equipment, the light rail industry, and more.

Call today to find out if we are right for your metal fabrication needs. 763-777-8087